Precision Acoustics is a global manufacturer of acoustic measurement products to medical, NDT (non-destructive testing) and academic establishments.

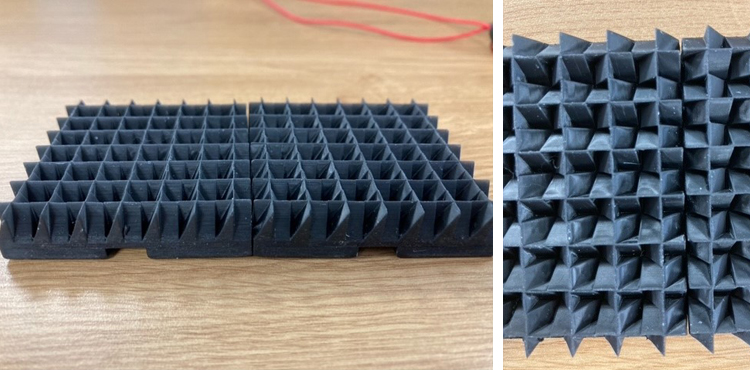

Originally, the Precision Acoustics team planned to produce the lining through a moulding process. However, earlier attempts to manufacture the mould, alongside further discussions with manufacturers, highlighted challenges associated with the geometry and size of the lining. The only viable solution was to 3D print the lining in sections, but this caused issues with precision and ease of assembly, as well as achieving the required finish to the product.

In speaking with the High Value Manufacturing Catapult (HVMC), Precision Acoustics were introduced to the MTC to explore alternative solutions.

In order to meet the customer’s requirements for this project, the MTC team first outlined a strategy for manufacture. Central to this was technology and material selection, which was determined by a detailed assessment process, working in collaboration with Precision Acoustics.

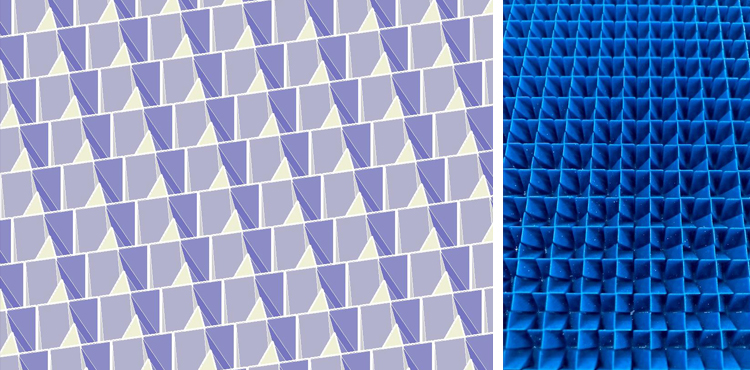

The MTC’s additive manufacturing team then looked at the possibility of using their large build envelope 3D printer, a Stratasys Objet 1000, to produce a full-size lining template out of a simulated polypropylene material called Rigur RGD450. Chosen for its mechanical properties and surface finish, the template would enable Precision Acoustics to produce a soft mould from silicone.

This did present some uncertainties, for example, the geometrical intricacies in the design could lead to some features of the lining template being at risk of breaking in the silicone mould. Furthermore, because the material was the most significant contributor to the overall cost of producing the template, the MTC team built smaller test parts first, before committing to a full-size build.

The iterations also tested against warpage; a concern due to the size of the product when it would be manufactured at full-size. Design adjustments were made during the three trial phases, after which point, the proposed final specification of the full-size template was agreed.

The MTC’s additive manufacturing team not only identified a suitable material and technology combination in order to meet product specifications, but it was also able to achieve this in a cost-effective manner.

The original design of the lining was adapted during the trial phases in collaboration with Precision Acoustics, with the MTC team drawing upon their expertise and experience of past projects to develop a viable solution. The project was also completed in a short timeframe, to enable the customer to proceed with the launch of new products.